últimas notícias

Categorias de Produtos

Quente Produtos

-

Mesa de tênis de mesa premium para campeonatos Volant King

Esta tabela de tênis de mesa premium é adequada para campeonatos. Aprovado pela ITTF e NSCC. Silver Undercarriage + Blue Light

consulte Mais informação -

Mesa de tênis de mesa oficial para torneio Volant Dream 2

Mesa de ping pong oficial Volant Dream 2 para competições internacionais desenhadas pela Double Fish Sports.

consulte Mais informação -

Mesa de tênis de mesa oficial para competições XIANGYU 328

Mesa de tênis de mesa portátil dobrável e duplo premium, design compacto O novo sistema de dobramento minimiza o risco de lesões durante o armazenamento e movimentação de mesa. Mesa de tênis de mesa aprovada pela ITTF.

consulte Mais informação -

Mesa de tênis de mesa oficial para turismo mundial 99-45B

ITTF aprovou a mesa oficial de tênis de mesa durável para o torneio internacional. Espessura da placa de mesa: 25mm QUALIDADE DO TORNEIO - Esta tabela de qualidade profissional foi projetada para o mais alto nível de competição. PERFEITO PARA FAMÍLIAS - Oferece uma peça premium para todas as idades. Vá de frente para a cabeça ou dobre para prática individual. Os suportes de aço pesado de 2 polegadas sustentam os desafios mais difíceis. Uma excelente peça central para a sala de jogos, a sala de estar ou a academia. EASY ASSEMBLY - Participe jogando em minutos com montagem simples. A rede de alta qualidade está equipada com grampos de bloqueio facilmente ligados.

consulte Mais informação -

Melhor qualidade Double Fish V40 + Volant 3 Stars Table Tennis Ball

Double Fish V40 + Volant 3 Stars Table Tennis Ball é confirmado para as últimas Normas Técnicas T3 da ITTF.

consulte Mais informação -

Double Fish QIJI All-round Table Tennis Blade

Lâmina de tênis de mesa QJJI de peixe duplo, que é a lâmina de tenis de mesa de tênis de mesa mais vendida, & nbsp; Perfeito para o jogador tradicional allround

consulte Mais informação

Rastreando a Origem | Desenvolvimento da Fábrica de Tênis de Mesa de Guangzhou (Parte 2)

Desde o outono de 1960, a Fábrica de Tênis de Mesa Chenggong passou mais de dois anos em inovação tecnológica, que basicamente mecanizou os principais processos de produção da fábrica até o final de 1963, melhorou a produção e a qualidade dos produtos e começou a exportar produtos. Em 1963, a produção foi de 3,2 milhões, mais de três vezes os 780.000 em 1960, dos quais 58.400 foram exportados.

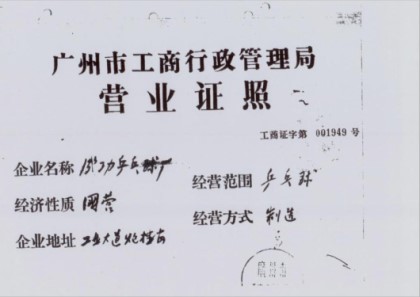

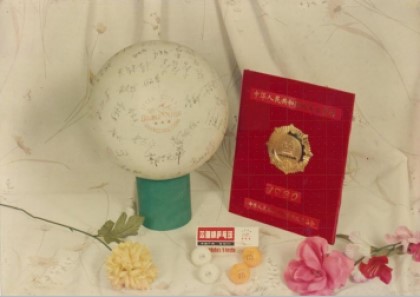

Licença comercial da fábrica de tênis de mesa Chenggong

① O conteúdo deste artigo é baseado principalmente nos dados históricos da Fábrica de Tênis de Mesa Chenggong e nas 303-304 páginas do Volume 5 (Parte 1) de "Crônicas da Cidade de Guangzhou".

No entanto, no momento em que a produção da Fábrica de Tênis de Mesa Chenggong estava crescendo, a escassez de recursos hídricos na área do Templo Polo tornou-se um novo problema que restringiu o desenvolvimento. No final, o departamento superior decidiu mudar a Fábrica de Tênis de Mesa Chenggong para Paolougang, próximo à Avenida Industrial Henan ②, para resolver o problema da escassez de água e expandir ainda mais a escala de produção. Esta mudança marcou o início de um novo capítulo no desenvolvimento da Fábrica Chenggong.

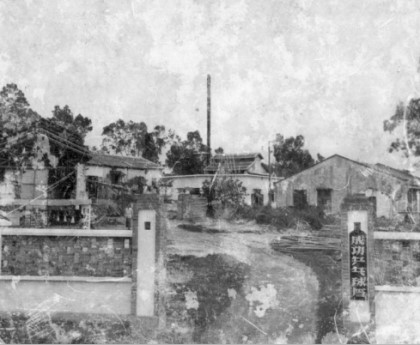

A fábrica de tênis de mesa Chenggong mudou para Yanzigang, distrito de Haizhu

②Paolougang próximo à Avenida Industrial Henan é agora a área de Yanzigang no distrito de Haizhu. A partir de 1952, o subúrbio de "Henan" em Guangzhou foi construído como uma importante base industrial em Guangzhou. Esta avenida já foi o coração da indústria de Guangzhou e deu origem a muitas inovações nacionais. Em seu apogeu, a Avenida Industrial de 5,5 quilômetros de extensão produzia produtos populares em todo o país, como geladeiras Wanbao, baterias Tiger Head, bicicletas Wuyang, etc. , que já contava com instalações fabris básicas, o que proporcionava comodidade para a expansão da produção. Com o forte apoio da unidade superior, a Fábrica de Tênis de Mesa Chenggong conseguiu adquirir um terreno e iniciar a construção, estabelecendo assim uma base sólida para o desenvolvimento futuro.

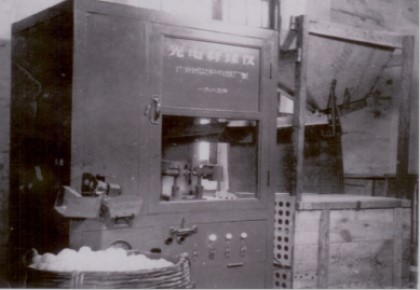

Em 1965, a Fábrica de Tênis de Mesa Chenggong alcançou outro sucesso ao desenvolver a primeira balança fotoelétrica de bolas do meu país. Em seguida, fabricou sucessivamente máquina automática de medição do centro de gravidade, máquina automática de impressão de marcas registradas, máquina automática de corte de bordas e máquina de medição automática, etc., e assumiu a liderança na realização da produção semiautomática e automática de tênis de mesa na mesma indústria em todo o país. Em 1966, a produção de bolas de tênis de mesa ultrapassou 10 milhões. Durante a “Revolução Cultural”, fundiu-se com algumas fábricas e também produziu tiristores.

In 1965, Chenggong Table Tennis Factory pioneered my country's first photoelectric ball weighing instrument.

Automatic label printing machine developed by Chenggong Table Tennis Factory

In 1968, with the support and coordination of the local government, Chenggong Table Tennis Factory merged with Huada Badminton Factory③ and Zhendong Sports Goods Factory④ , significantly improving the productivity of the enterprise. Subsequently in 1969, the factory was renamed Guangzhou Sporting Goods Factory, marking the expansion of its product categories and business scope.

③According to the "Chronicles of Guangzhou City", the production of badminton in Guangzhou began in the early 1950s. With the rise of badminton, the production households continued to develop and gradually organized themselves. In 1956, the Yongjian Badminton Production Cooperative and the Yufeng Production Cooperative were formed. In 1960, the Yongjian Society was renamed the Huada Badminton Factory, with 100 employees. In 1964, the World Games brand badminton of the Yufeng Society was rated as a famous brand product in Guangzhou. During the "Cultural Revolution", all badminton production cooperatives were merged into the Chenggong Table Tennis Factory.

④Zhendong Sports Goods Factory mainly produced wooden-handled skipping ropes, table tennis nets, and volleyball nets. Before the merger, the two factories were located on the streets in the urban area, with scattered and narrow factory buildings (all old residential buildings), making material transportation and management extremely inconvenient. The merger improved the production conditions of such products. This article is compiled based on the oral narration of the retired leaders of Guangzhou Table Tennis Factory.

In 1972, the company was renamed Guangzhou Table Tennis Factory. In the same year, Guangzhou Table Tennis Factory introduced the innovative wax expansion method, replacing the old steaming process for producing close-seam balls, which doubled the work efficiency. The introduction of this technology not only improved production efficiency, but also made Guangzhou Table Tennis Factory the first company in China to achieve full mechanization of close-seam ball production.

Table tennis ball expander from the mid-1970s

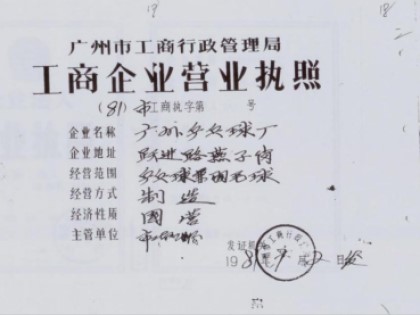

Guangzhou Table Tennis Factory Business License

In 1974, after five months of unremitting efforts and more than 130 precision tests, the Guangzhou Table Tennis Factory successfully developed China's first hard table tennis ball. This achievement marked a major breakthrough in China's table tennis manufacturing technology. The product was subsequently named "Shuangyu Brand". In 1979, this table tennis ball was officially approved by the International Table Tennis Federation and became the designated ball for international official competitions.

In 1980, "Double Fish" brand table tennis balls were officially rated as a national famous trademark and won the National Gold Award in the same year.

Doublefish table tennis won the national gold medal certificate

In 1981, with the booming domestic and foreign markets for badminton, the Guangzhou Table Tennis Factory restarted the production of badminton with the formal approval of the competent authorities. It focused on creating special balls for high- and mid-end competitions, strictly selected high-quality white goose feathers, and used imported cork and artificial leather as ball head materials to produce badminton with excellent whiteness, strong flight stability, and precise landing points. All products were sold to the Japanese market.

From 1986 to 1990, the annual output of badminton achieved an average high growth rate of 31%. In 1989, advanced Japanese production equipment was introduced, which greatly improved the production capacity and reached an annual production capacity of 24 million. In 1987, the Jinque brand badminton in the domestic market was rated as a high-quality product by the Ministry of Light Industry, and in 1990 it won the official certification of the national competition ball, marking the full recognition of product quality and technical level.

In 1986, as sales continued to expand, Guangzhou Table Tennis Factory set up branch factories in Zengcheng and Huaxian (now Huadu District, Guangzhou), focusing on producing mass-market table tennis balls to meet domestic market demand, while the main factory was committed to producing mid- and high-end table tennis balls for export. In 1987, total production soared to 63.02 million, of which 54.82 million were sold to overseas markets, generating US$2.18 million in foreign exchange revenue.

In 1988, the outstanding performance of Guangzhou Table Tennis Factory won the honorary titles of Provincial Advanced Enterprise and National Second-Class Enterprise. In 1990, Guangzhou Table Tennis Factory invested 2.5 million yuan in factory construction and technical transformation to further improve production capacity. In November of the same year, a new celluloid sheet plant was established in Zengcheng with an investment of nearly 2.57 million yuan. Through this series of transformation and expansion, the annual production capacity of table tennis balls doubled from 60 million to 120 million, making Guangzhou Table Tennis Factory one of the important bases for table tennis ball production in the world.

Guangzhou Table Tennis Factory in the 1990s

In 1994, the company relocated and expanded again⑤, requisitioned 50 mu of production land in Dabu Management District, Mayong Town, Dongguan City, relocated and renovated it, expanded its production scale, and achieved rapid improvement in production quality, laying a solid foundation for the company's sustainable development.

⑤ Como o principal componente do celulóide, matéria-prima para a produção de tênis de mesa, é a nitrocelulose, esse material é extremamente inflamável e causou muitos acidentes graves de incêndio na China, incluindo os acidentes de incêndio na fábrica de tênis de mesa Double Happiness em Xangai e em Tianjin. Fábrica de tênis de mesa. Em 14 de outubro de 1993, a Fábrica de Tênis de Mesa de Guangzhou também sofreu um incêndio, resultando no incêndio de 4.000 metros quadrados de edifícios. Além disso, o rápido crescimento das áreas residenciais perto de Yanzigang na década de 1990 tornou os riscos de segurança na área cada vez mais proeminentes. Diante disso, a Fábrica de Tênis de Mesa de Guangzhou decidiu realocar completamente sua linha de produção e transferi-la para Dongguan para garantir padrões de segurança mais elevados e eficiência de produção.

Fábrica de Dongguan na década de 1990

Em 1995, com base na influência significativa da marca "Doublefish" , a Guangzhou Table Tennis Factory mudou oficialmente seu nome para Guangzhou Doublefish Sports Goods Factory.

Em 26 de fevereiro de 1998, a Guangzhou Shuangyu Sporting Goods Factory foi incorporada pela Guangzhou Shuangyu Sporting Goods Group Co., Ltd.

Overseas business:(020)8431 9554

Overseas business:(020)8431 9554

13829778212

13829778212